Features:1.

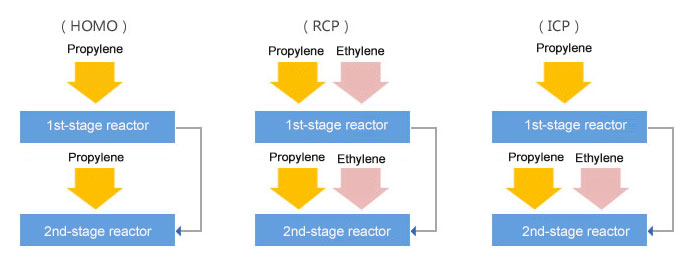

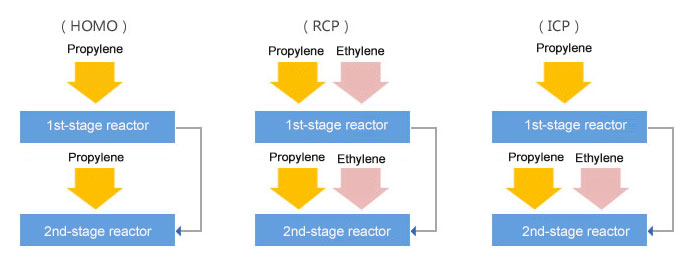

Two-stage gas phase method

2.

Horizontal reactor

3.

Piston spiral propeller

4.

Highly secure, low investment in equipment

5.

Both ordinary grades and special grades of high impact copolymer with high content of ethylene-propylene rubber can be produced.

Technical advantages:一、Compared to bulk polymerization

1. Precise control of the reaction process

2. No need of liquid recovery equipment

3. The catalyst is not easily aged

二、

Compared to the complete mixing tank reactor

1. Less bypass particles

2. Narrow residence time distribution in the reactor

3. Quick switch between different grades

4. The reactor does not require frequent cleaning

三、Compared to the other two-stage processes

1. The two-stage reactor can produce both homopolymers and copolymers at the same time

2. The equipment has high operating efficiency

3. Uniform and stable temperature control

Industrialization Level:There is a 300,000 ton equipment in Japan, two sets of 200,000 ton equipment in China, and some 100,000 ton or above equipment in other countries.

Description and pictures:  Recommended process route:

Recommended process route:With the development of China's coal chemical industry, the competition in olefins downstream products will be more intense. In the future market, product differentiation is one way to survive, so we recommend production technology for high-performance special grades of polypropylene.

1.

Propylene downstream processes in MTP and MTO projects

2.

Downstream processes in propane dehydrogenation projects

3.

Downstream processes in naphtha cracking projects.