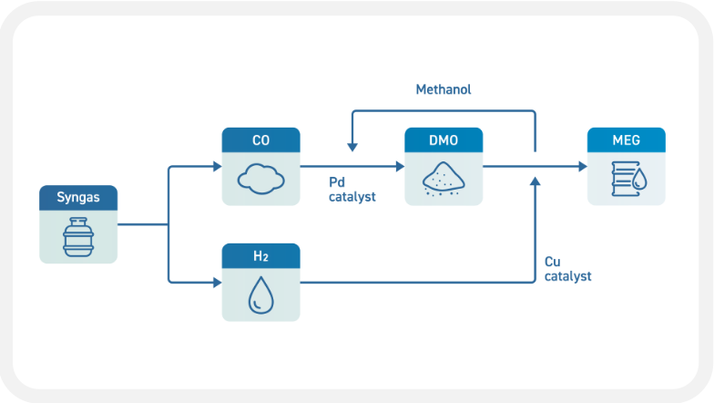

To distinguish from ethylene glycol via petroleum method (MEG), coal-to- ethylene-glycol method(SEG®) can also be called syngas method (SEG®). President of HighChem Company Limited Taka Ushio said “MEG will be finally replaced by SEG®,it is viewed as a major driving force to lead highchem group to stand on the world stage,not only in china market."this statement might be considered impossible one year ago,however,nowadays, when the first plant with 50,000 tons/year polyester grade SEG® ethylene glycol plant has run smoothly for 12 months.

According to incomplete statistics, as of December 30, 2013, Xinjiang Tianye’s glycol unit has run smoothly for 12 months. The cumulative production of glycol is about 43,000 tons, of which 40,000 tons are excellent grade, 3000 tons are qualified products. The operating load of the plant keeps at 95%, and the monthly average production load is 80%. The rate of high class glycol products exceeds 92%, and the product purity reaches 99.94%. It is the first SEG® plant in China.

In terms of economy, SEG® has obvious advantages. Production of ethylene glycol per ton consumes 0.68 ton ethylene by ethylene method. Calculated by 8,000 RMB per ton (ethylene), the cost of raw materials is 5,440 RMB. While SEG® method is much cheaper. The cost of raw materials is about 2,450 RMB per ton calculated by 450 RMB per ton (coal). What’s more, the SEG® method requires less investment in the production facilities.

In terms of technical aspect, there are some difficulties for Chinese companies to apply SEG® technology, such as the catalyst problems, the potential safety risks of methyl nitrite(MN) generated during the production of glycol, as well as the technological bottleneck – cannot produce high-end glycol products. HighChem is dealing with this problem.

February 2013, the catalyst plant invested by HighChem was successfully put into production in Nantong. The production scale of the first phase will reach annual output of 3,000 tons/year. It will be able to provide catalyst and catalyst backup services for SEG® production of 3 million tons per year. The actual operation in Xinjiang Tianye has proved the superiority of the catalyst performance.

As for the MN safety risks, industry experts say that Chinese technology still needs to work on the monitoring of MN concentration. While UBE has accumulated rich experience in MN safety control with 30 years of research and operation. HighChem turned a new leaf in producing high class glycol products in 2013. Through running the gas phase reaction at 100% operating ratio immediately when feeding the raw materials, Xinjiang Tianye produced high-end glycol product in a short time, and exceeds 92%.

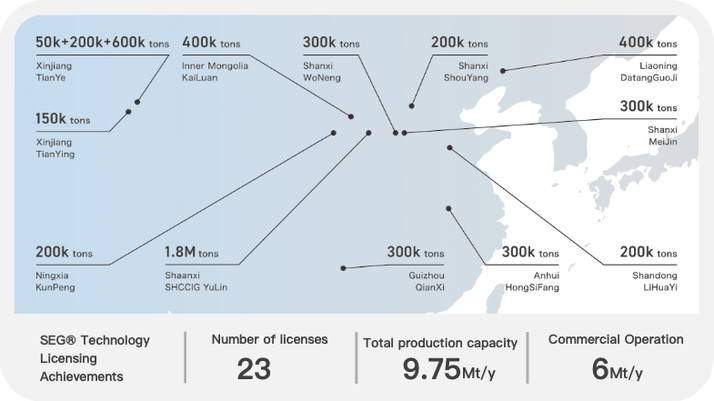

Today,coal chemical industry is undergoing a flourish development in China,Highchem with SEG® is holding the chance, standing on the China Chemical stage.Highchem wants to do more than what it has been doing, showing its resolution and courage to be a comprehensive technology supplier.